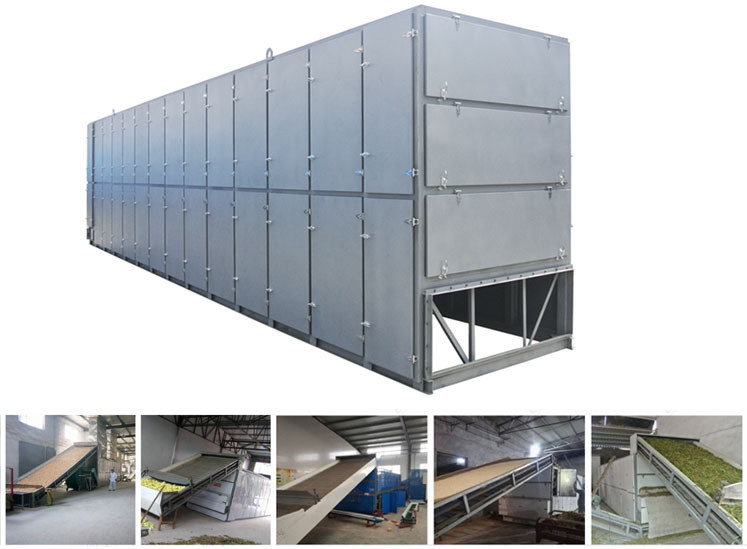

Mesh belt dryer fruit and vegetable drying machine can meet to dry different vegetables such as, root, halm, leaf, tuberous root, big granule and produce in batch. The machine owns the advantages, of fast drying speed, high evaporation capacity and good product quality. The equipment main use is the material through the conveyor belt to the top of the dryer, the material on most of the water droplets removed, and then through the multi-layer conveyor belt round-trip transport, so that the material in the process of transmission automatically flipped, so that the material in each part of the moisture can be fully in contact with hot air and vaporize evaporation, to achieve the purpose of drying de-water.

Features of multi-layer mesh belt vegetable dryer:

Air volume, heating temperature, material retention time and feeding speed can be adjusted to achieve the best drying effect.

Flexible equipment configuration.Mesh belt flushing system and material cooling system can be used.

Most of the air is recycled with high energy efficiency.

Unique air distributor makes the distribution of hot air more even and ensures the consistency of product quality.

The heat source can be steam, heat conduction oil or gas stove.

The material is evenly spread on the mesh belt by the feeder. The mesh belt adopts 12~60 mesh stainless steel mesh, which is dragged by the transmission device to move in the dryer. The dryer is composed of several units. The circulation of hot air in each unit is independent, in which part of the exhaust gas is discharged by a special dehumidification fan, and the exhaust gas volume of each unit is controlled by a regulating valve. For dehydrated vegetables, three devices are used generally in series to form the initial drying section, the middle section and the final drying section. In the initial dry section, due to the high water content and poor air permeability of the material, the material is paved with a smaller thickness for faster running speed and higher drying temperature. The temperature of dry gas can reach above 120℃. The material residence time in the final drying section is 3~6 times that of the initial drying section, and the thickness of the paving material is 2~4 times that of the initial drying section. For the requirement that the temperature of material can not exceed 60℃, dry gas of about 80℃ can be used. Adopting multi-stage combination of drying can give full play to the performance of mesh belt dryer and the drying effect is more uniform.

The vegetable dryer is widely used in the dehydration and drying of food, aquatic products, agricultural and sideline products, dehydrated vegetables, Chinese medicinal materials, feed and chemical raw materials.

Fruit: Almonds, jujube, peanuts, longans, walnut, papaya tablets, apple, lemon, hawthorn pills, bananas, etc.

Vegetable: Asparagus, beans, kidney beans, lentils, eggplant, red pepper, Chinese prickly ash, black fungus, tremella, papaya tablets, pills, bitter melon, radish, cucumber slices, mushrooms, mushrooms, ginger, garlic, hot pepper etc.

Others: Lily, rose, peony seed, fennel seeds, etc.

The vegetable drying equipment has compact structure, small floor space, simple operation, convenient maintenance and stable operation.